How does it works?

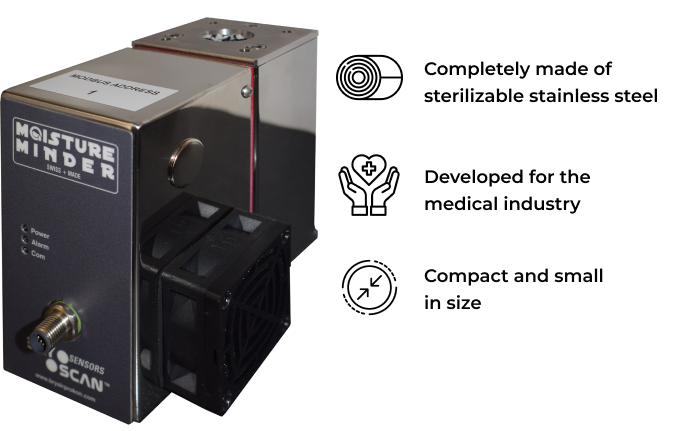

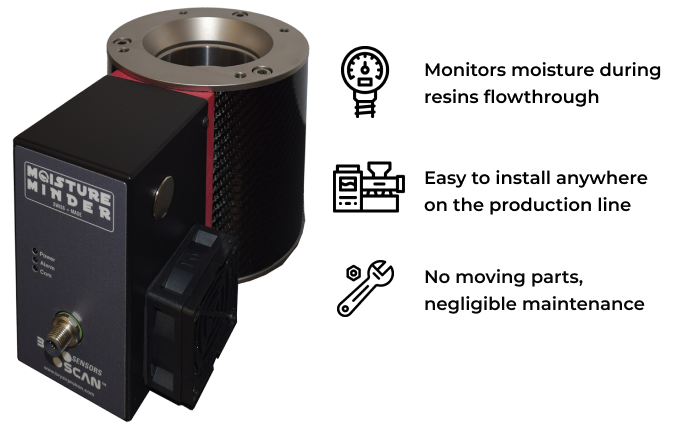

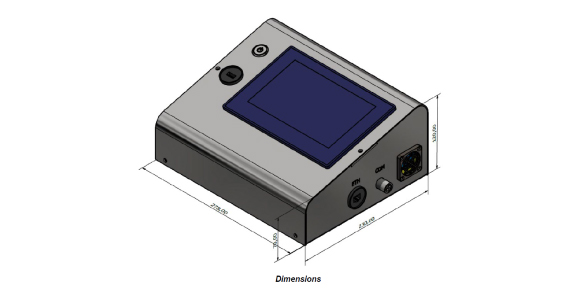

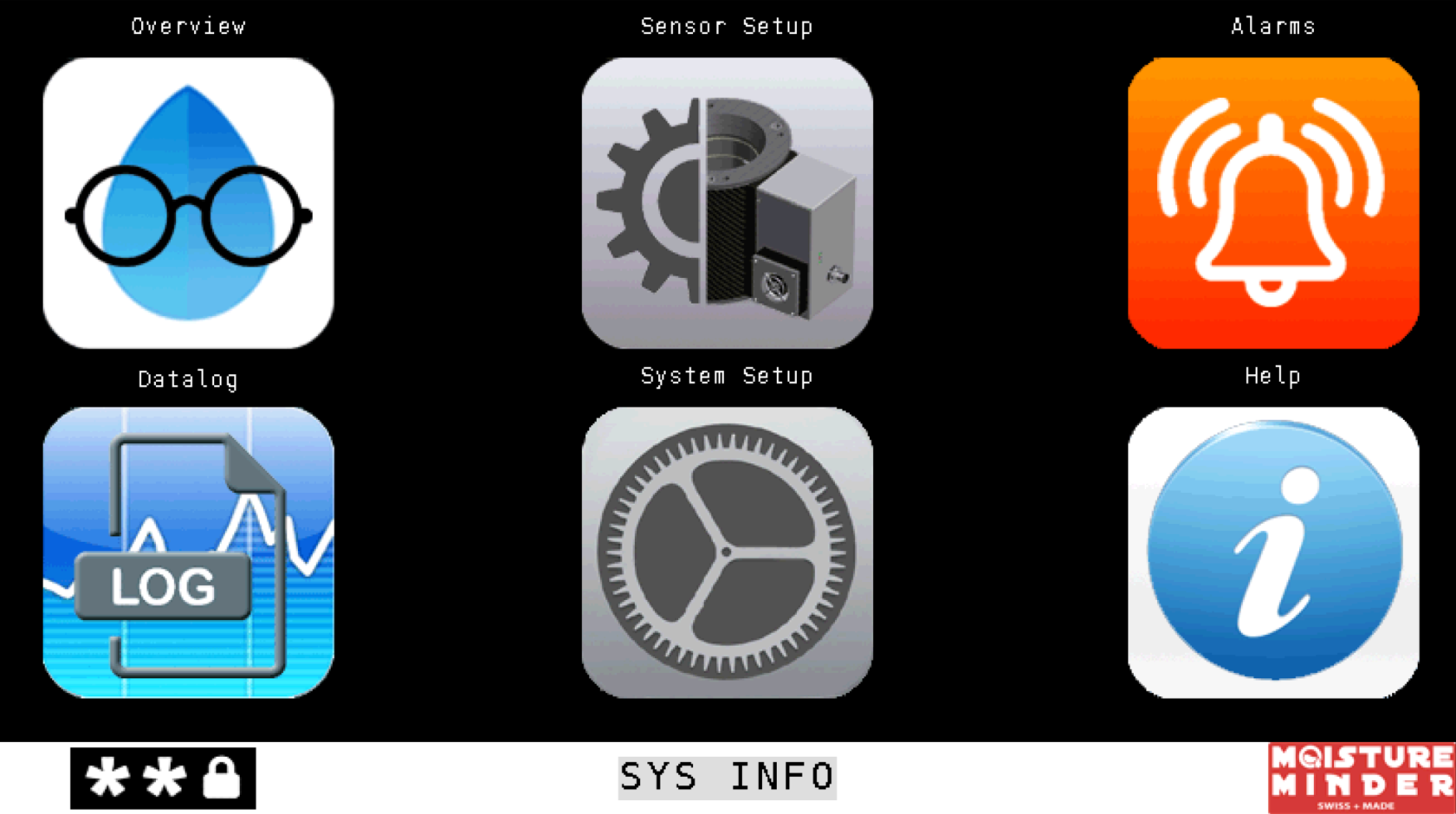

The Moisture MinderTM accurately displays the actual moisture content of plastic pellets or regrind, in % or PPM (parts per million). Moisture MinderTM sensors can be retrofitted to virtually any drying hopper, silo, material line or machine throat and the moisture analysis is displayed on a 7” Color touch screen control which up to 8 sensors can be connected simultaneously. Trending screens are standard on the controls and options are available to divert or re-circulate material that is not within your dryness specifications. Furthermore, it is possible to integrate the data directly into your supervisors via the Modbus TCP/IP protocol available in our control system